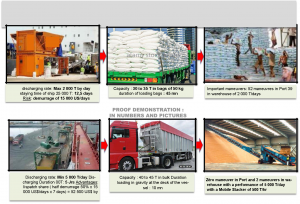

Logistic Bagging chain :stacking in warehouse

| 1 – RECEPT OF PLANQUETS IN WAREHOUSE | 2 – STACKING OF PLANQUETS | |

| 3 – REHANDLING OF PLANQUETS IN WAREHOUSE | ||

| 4 – LOADING OF TRUCKS |

WHY AND HOW TO TRANFER BAGS TOWARD WAREHOUSE ?

Liberating ships from following constraints and aleas :

- Bagging machines break

- faillure of located trucks and loading bags by maneuvers on trucks

- Faillure of maneuvers loading bags in warehouse

SHIPPING AGENCY

• Réduction of port congestion means reduc • of waiting at anchorage, Elimination constraints and unusefull aléas on • ships décharging , Discharging rate pass on a maximum of 2.000 T/days at a minimum of • 5.000 T/day, Ship of 25 000 T staying pass from 12,5 days to 5 days; so Divided by par • 2,5, Discharging during national feast become possible due reduction see nul on main maneuver, * Ships port charges and fees are reduce on maximum • Dakar Port attraction will increase

PORT HANDLING

• Get advantage of board shore handling of 5 000 T by 24 hourss garanted by TVS with a ableaccept tariff, • Evoid big cost of bagging • of TVS, Elimination of break risk from bagging machine, • Use of big size hoppers d • passing from 10 to 30 T, Use of big size of Grabs • passing from 5 to 12 T, Dockers performance is separated to maneuvres • who are bagging, Réduction Dockers Number from 108 to 81 and Multiplication by 4 of their productivity, • Reduction of Dockers cost, • Zero Maneuvre on deck for the loading of tipper in aluminium

EXTRAPORTAGE TOWARD WAREHOUSE

• Elimination of risk of maneuvers lack for the trucks • loading Trucks loading is done in gravity and duration pass from • 45 mn to 10 mn, Cappacity ofTipper in aluminium (45 Tonnes) is 50% supérior of plate • trucks d (30T), Tipper mécanics liftback what is reducing duration of discharging in warehhouse

WAREHOUSING

• Elimination of the risk of lack of maneuvers to unload and stack the bags, • Improvement of the "Foot print Ton / m2" ratio, which doubles from 3 T / • m2 to 6 T / m2, Reduced cost of • storage, Drastic reduction • of warehouse staff, Fast replenishment of bulk fertilizers with a loader • shovel, Elimination of human contact with the stock during unloading, • Continuation of operations before and after national holidays

RECEPT AT LE CUSTOMER

• Reconditioning of fertilizer à la carte • (big bag or bags), Elimination of unnecessary costs related to bagging for Bulk blenders • customers, Perception of, • Time supervision of unloading vessel is • divided by 2.5, Reduced maritime • freight, Cargo weighing is independent of the empty weight of the • bags, Despatch of US $ 52,500 / Ship of 25,000 T, US $ 2.1 / T,